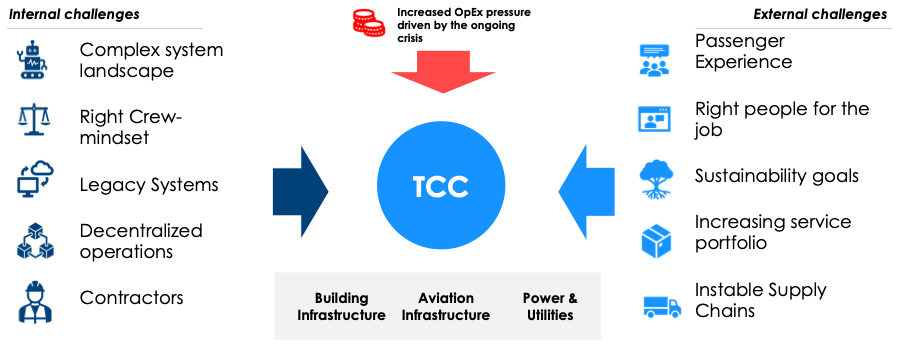

Three major factors that require airport operators to constantly examine and optimize their technical departments for operational success:

- New and tightening regulatory and environmental requirements are driving the technical complexity andmaking terminals, facilities and systems more complex and difficult to operate.

- With so many airports vying for returning customers, those that provide the best experience will win out in the end.

- Continued introduction of ever-advancing technologies is increasing expectations and objectives within the organization. It is therefore crucial to keep a finger on the pulse of technological developments and remain ahead of the curve.

Here’s why you should take on these challenges at your technical control center and which three major levers lead your transformation project to success.

How Technical Control Centers are impacting airport operations

Technical Control Centers are an important part of operating an airport and play a vital role behind the scenes.They sit at the center of incident response and technical services and thus play a crucial role in customer satisfaction and the response effectiveness.

In today’s competitive environment, airports must differentiate themselves on the basis of perceived quality – especially in a weak demand environment where they are vying for traffic volumes. This perception is materially influenced by the ability of the airport’s technical maintenance staff to quickly repair faulty facilities and fix problems – ideally before a passenger even notices it. The staff in the Technical Control Center play a key role in this, as they are the face of the facility management organization to the customer, including the operational departments, airlines, commercial tenants and ultimately the passenger.

The way TCC staff react to a report is crucial in determining how effective the facility management department’s response will be, and consequently, how much it will cost. This is due to the nature of a TCC agent’s role as a communications interface. When an issue is first reported, they must identify and extract all relevant information to make a qualified decision to pass on the right team, engineer or expert, along with the most appropriate action required, as well as the issue’s priority. A correct initial judgement by a TCC agent can thus substantially save time and effort along the process throughout the entire FM department. Of course, a number of faults will seem mundane and can easily be fixed (think: “have your tried turning it off and on again?”). Others, however, will be much more critical in terms of the parties or processes affected and the urgency they need to be investigated and solved. The key to maximizing added value is to automate the handling of routine cases, freeing up time to focus on complex and difficult cases individually.

Moments of actual crisis are a third example for the important role Technical Control Centers can play. Be it a child stuck in an elevator or a complete breakdown of the baggage handling system, low reaction times are key to salvage situations before they spin out of control. In such instances, pressure on the entire system rises exponentially, quickly exposing any interfaces or processes that are not up to standard. Airports’ Technical Control Centers can then demonstrate whether they are a solution driver or the weakest link in the response chain.

M2P’s view: drivers of complexity and fields of action

We have experienced first-hand the reoccurring themes that either drive or impact the effectiveness of technical control centers. Here are the ones that we consider to be the most important.

Control centers are in an integral position to the entire incident management process. Yet, it often seems that management’s view is rather isolated, i.e. not capturing the full picture: Is the control center seen as an isolated cost center or is it possible to actually determine cost and value contribution along the entire process?

While tracking the Center’s direct staff or IT costs is fairly straight forward, getting an end-to-end view on total cost of maintenance is significantly harder to obtain. In many cases, this would lead to improved decision making.

Take the example of the Agents’ intra-day decision-making and evaluation of criticality: an isolated perspective naturally fosters short decision-making on a first-come-first-serve basis. With a better understanding of associated downstream costs along the process, repair jobs could be combined to help reduce the overall cost.

Similarly, demand patterns are often insufficiently known or at least considered. Indeed, a good share of incidents coming in via the various channels (phone, email, platforms, BMS systems) is random. A more thorough analysis might, however, reveal certain patterns across weekdays, daytimes and seasons. Contrary to that is the Center’s shift plan which is often based on a more rigid regime. This could lead to structural idle time being left untapped, or even worse, fundamental understaffing during critical peaks. The consequence of taking isolated views on interdependent issues are inappropriate incentives for optimization of the Control Center. Failing to invest in this function has far-reaching consequences that would benefit the whole department further down the process chain.

Operational inefficiencies and outdated or unaligned tools

Staff can perform to the best of their abilities and with maximum efficiency when they are supported by effective systems.

Historically driven, Control Centers often include a range of systems in use: Different buildings run on various Building Management Systems (BMS), protocol and communication systems have been added over the years. In this context, integration is often considered cumbersome and expensive. On top of this, constantly increasing requirements lead to further expansions to the IT portfolio, adding more complexity. Automation is hard to achieve in such heterogenous system landscapes. The manual tranfer of data between systems as a result provokes mistakes. Additionally, a lacking or incomplete integration of BMS prevents staff from effective system surveillance.

Another decisive contributor to performance is the effective organization of procedures and processes within the Control Center. On this front we have mostly observed a very generalist approach, with a broad range of topics and systems being covered by all agents. Irrespective of individual’s skill and knowledge, both decrease motivation as some agents find specialist tasks daunting and others’ expertise is “wasted” performing repetitive tasks. In addition, tasks are predominantly fulfilled manually, and on a case-by-case basis, revealing how a lack of automation is slowing down processes and creating extra procedural steps.

Even though technical equipment and support is of the essence, it eventually comes down to the people and the purpose they find in their jobs. Staff in control centers are regularly met with a variety of different expectations. Customers or passengers expect a maximum of service quality: both in terms of friendliness as well as the agent’s ability to identify and solve problems and give appropriate feedback. On the other hand they require broad technical expertise and analytical skills to properly manage and maintain the technical systems in collaboration with the operational technical and engineers.

Given their professional background and daily routine, employees in control centers often tend to have a culture of technical expertise, neglecting their impact on customer experience. Considering their position at the airport, it becomes evident why: control centers are often isolated from the actual operation, only having remote contact with customers and peer workers. This lack of recognition leads to agents feeling undervalued and unappreciated in their work, affecting not just them but also the department and company as a whole. Eventually, they perceive a lack of definition regarding their roles, feeling a disconnect between their work and the value it provides overall.

People remain at the center of any successful change or improvement

It is the responsibility of senior and direct management to define a culture that balances service and technical orientation, while also making sure the unit is properly represented within the entirety of the airport. Culture and mindset should eventually follow the company’s overall strategic objectives: be it running on lowest cost or at highest service levels. When senior managers make it clear whether the Technical Control Center is to act primarily service-oriented or as a technical advisory function, they set the stage not only for agent’s self-image, but also how the unit will be perceived by the rest of the company. Having a firmly embedded Control Center into the overall facility management strategy allows for its senior managers to easily highlight any potential shortcomings to the wider company.To leverage the full potential of Control Centers as an enabler for a nimble, cost-efficient and customer-centric maintenance organization, companies should seek a strategy to operations alignment.

Concretely, this means that facility managers must be clear on what is expected from Control Centers, and how they fit into the overall maintenance organization. This includes strategic direction on service-orientation and technical priorities as well as streamlined processes and supporting tools.

If the Control Center is not firmly embedded into the overall facility management strategy and does not have a clearly defined objective, it will not be possible to fully leverage its position.

Based on the this, we see three major levers to prepare the control center for the next era of smart airport operations:

1. Next Level IT-to-Operations Integration

As in any industry, automation and digitalization are the key levers to drive performance improvement. In the context of control centers it is all about getting ahead of the demand curve: the less agents are occupied with reacting to incoming calls, the more they can focus on surveilling systems and predicting incidents before they become visible to the customer.

A seamless integration of IT systems and facility management processes is key to acheving this. AI driven systems are able to predict patterns and derive incident forecasts, thus reducing the amount of reactive intervention required from agents. Providing digital twins of facilities to agents will allow them to get better at identifying problems and dispatching technicians, in turn strongly increasing KPIs such as the first time fix rate. A full-fledged integration of systems – from the client to the workshop – will facilitate an efficient set-up of end-to-end processes and improved service delivery to the customer. Both will help support a necessary cultural shift in the self-image of Control Center staff – from someone manning a phone to a proactive steering of facility operations.

2. Reorganize Work Allocation and raise efficiencies

A Control Center should not have a “one-size-fits-all” approach to work allocation. Instead, the Center’s processes can be split into recording and allocating reports on the front end, and decision-making on priorities and technical approaches on the back end. This increases efficiency by allowing staff to focus on critical and value-generating tasks, respectively, thus boosting morale and engagement as individual qualifications are factored in and acknowledged.

Ideally, splitting the tasks this way is based on a sound IT backbone supporting automation, report interpretation and allocation for further action. While such reorganization will certainly require a concerted change management effort, the eventually gained improvement in effectiveness will increase room to maneuver. By centralizing more functions into the center, we can increase efficiency, speed, and productivity. Alternatively, certain functions could be combined into one center across various sites, greatly improving productivity.

3. Workforce Empowerment

People will remain at the center of any improvement. Similarly, the expecations and tasks of control centers will continue to rise, despite the latest crisis. To better meet those expectations, it is essential to find a new approach towards hiring and developing the most suitable agents. With an increased split of tasks, it will be possible to move beyond developing everyone to the same level. By building upon individual strengths and preferences, agents will be able to strengthen their performance and improve job satisfaction. While experienced technical experts can focus on solving and managing complex technical issues, service professionals will be allowed to deliver a premium customer experience. This is completed by IT experts driving system integration and facility automation.

Conclusion

With the right approach, airport‘s technical control centers can become a huge contributer to smart airport operations by focusing on IT integration, competency-based work allocation, and workforce empowerment. By ensuring the Technical Control Center drives efficient facility management processes, this creates a premium customer experience.

Speak to an expert

Hear us talking about Smart Airport Operations at the PTE in Paris!